MATHEMATICAL CORRELATIONS FOR DETERMINING THE SPECIFIC MASS OF FRUIT PULPS AS A FUNCTION OF TEMPERATURE

ISBN 978-85-85905-25-5

Área

Alimentos

Autores

Ramos, M.L. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Silva, F.V.S. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Pereira, P.V.D. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Rodrigues, F.M. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Viroli, S.L.M. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Ferreira, L.C. (IFTO CAMPUS PARAÍSO DO TOCANTINS) ; Santos, M.R. (IFTO CAMPUS PARAÍSO DO TOCANTINS)

Resumo

The objective of this work was to determine the behavior of the specific mass of guava and mango pulps at different temperatures and to propose a specific polynomial model to predict this property. The specific mass of guava and mango pulps were determined using pycnometers at temperatures of 20 to 60 °C. The specific mass of guava and mango pulps ranged from 1034,23 to 1070,0 kg.m-3 and from 1034,23 to 1070,01 kg.m-3 respectively. The polynomial model that fit the experimental data was the four-term polynomial model.

Palavras chaves

mango; specific mass; guava

Introdução

Density, specific heat, conductivity and thermal diffusivity are important thermophysical properties for designing and sizing heat transfer equipment and processes (MATTOS, J.S.; MEDEROS, B. J. T., 2008). The handling, transportation and storage of fruit pulp involve important physical properties for the correct sizing of the equipment intended for these operations. (LIMA, 2003). In fruit processing the proper sizing of the equipment represents excessive profit of economy and energy. Consequently, it is essential to know the behavior of the specific pulp mass under processing conditions as it changes during heat and mass transfer during food processing (Bolzan and Souza, 2007). Fruit pulp processing is an economic activity that adds value to fruit, prevents waste and reduces losses during the marketing of fresh fruit (NASCIMENTO et al., 2013). During the pulp processing, heating, pasteurization, concentration and the use of low temperatures are used to preserve the quality of these products. (LIMA, 2003). Mathematical models for predictability of thermophysical properties represent an appropriateness of increasing the efficiency of heat treatments in food processing and an alternative to replacing the experimental determination of these parameters, which can be very costly for industry (EGEA et al., 2015). Given the above, the present work was developed to determine the behavior of the specific mass of guava and mango pulps and to propose a specific polynomial model to predict this property.

Material e métodos

This work was carried out at the Food Laboratory of the Federal Institute of Tocantins - IFTO Paraíso do Tocantins campus, from August to December 2018. Mango and frozen guava pulp were purchased at the local commerce of Paraíso do Tocantins - TO. The analyzed chemical physical parameters hydrogen potential (pH), titratable total acidity analysis, soluble solids and vitamin C analysis followed the methodologies indicated by the Adolf Lutz Institute (IAL. 2008). The specific mass of guava (Psidium guajava) and mango (Mangifera indica L) pulp was determined at temperatures of 20, 30, 40, 50 and 60 ° C following the method described by AOAC (1984). The specific mass calculation was performed through the equation ρ = m / v where, (ρ) Specific mass of product (kg.m-3); (v) Pycnometer volume (m3); (m) Product mass (kg).Regarding the mathematical modeling of the specific mass of mango and guava pulps, the linear polynomial models ρ = a + bT were used; quadratic ρ = a + bT + cT²; and third degree ρ = a + bT + cT2 + dT3 where T = Temperature (° C); a, b, c and d - constants. The degree of fit of each model was considered by the magnitude of the coefficient of determination (R²). Linear regressions of the specific mass data were made to obtain the equations that represent this magnitude, using the Assistat computer program. All experiments were performed in triplicate and the calculation was used to average the values obtained in the experiments.

Resultado e discussão

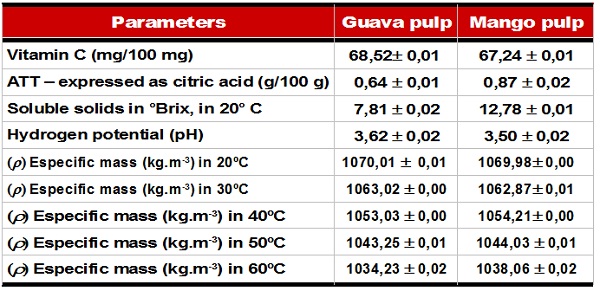

Table 1 shows the experimental values of the specific mass of guava pulp and

mango pulp at temperatures of 20°, 30°, 40°, 50° and 60ºC.

TABLE 1 - Physical and chemical parameters of frozen fruit pulp marketed in

the

central region of Paraíso do TocantinsThe average values of guava pulp

specific

mass ranged from 1034,23 to 1070,01 kg.m-3 with a concentration

of

7,81 ºBrix and for mango pulp ranged from 1038,06 to 1069,98

kg.m-3

with a concentration of 12,78 ºBrix and the significant decrease in the

average

values of the guava and mango pulp specific mass with increasing

temperature.

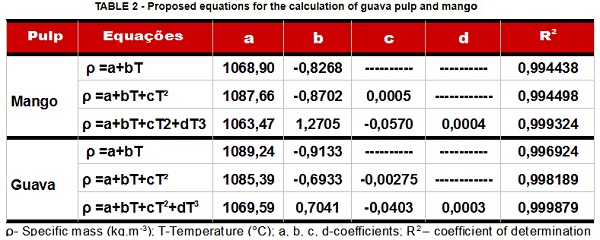

TABLE 2 - Proposed equations for the calculation of guava pulp and mango

pulp

specific mass as a function of temperature.Table 2 presents three models

represented by polynomial equations proposed for the calculation of the

guava

pulp specific mass as a function of temperature and their respective

determination coefficients. The polynomial model that best fit the fruit

pulp

experimental data, considering the highest coefficient of determination,

were

the four-term polynomial models, with R2 = 0,999879 for guava

pulp

and R2 = 0,9999324 for pulp. Mango Diniz et al. (2014) obtained

values f specific mass for guava pulp, with 12,1 ºBrix and temperatures from

10

to 50ºC, equal to 1115,92 to 1070,64 kg.m-3. Dantas Junior et al.

(2007), estimating the specific mass of mango pulp through the linear and

quadratic equations, found that both equations can be used to estimate the

specific mass of sword mango pulp as a function of temperature. Guava and

mango

pulp specific mass values decreased with increasing temperature, probably

due to

the volumetric expansion of the fluid caused by reduced intermolecular force

bonding.

Conclusões

The specific mass of guava and mango pulps ranged from 1034,23 to 1070.01 kg.m-3 and from 1034,23 to 1070.01 kg.m-3 respectively at temperatures of 20 to 60ºC, with a reduction in of the specific pulp mass in relation to the temperatures studied in this work. The polynomial model that best fit the experimental data was the four-term polynomial model, as it presented the highest coefficient of determination R2= 0,999979 for guava pulp and R2 = 0,9999324 for mango pulp. The other two models could also be used, as they presented considering a good fit to the experimental data.

Agradecimentos

A DEUS AO IFTO CAMPUS PARAÍSO DO TOCANTINS AOS PROFESSORES FERNANDO MORAIS RODRIGUES, PAULO VITORINO DANTAS PEREIRA E SERGIO LUIS MELO VIROLI

Referências

BOLZAN, T. G.; SOUZA, D. Estudo do comportamento da massa especifica de suco de laranja em função da temperatura e da concentração. XIX Salão de iniciação científica, Livro de resumos. Porto Alegre: UFRGS, 2007.

EGEA, M. B.; REIS, M. H. M.; DANESI, E. D. G. Aplicação de modelos matemáticos preditivos para o cálculo das propriedades termofísicas do palmito pupunha. Revista Brasileira de Produtos Agroindustriais, v.17, n.2, p.179-187, 2015.

DANTAS JÚNIOR, E. E.; QUEIROZ, A. J. M.; FIGUEIREDO, R. M. F. Determinação e elaboração de modelos de predição da massa específica da manga espada. Revista Educação Agrícola Superior, v.22, n.1,p.39-42, 2007.

DINIZ, R. S.; COIMBRA, J. S.R.; MARTINS, M. A.; SANTOS, M. O. ;DINIZ, M. D. M. S.; SANTOS, E. S.; SANTÁNNA, D. D.; ROCHA, R. A.; OLIVEIRA, E. B. Physical Properties of Red Guava (Psidium guajava L.) Pulp as Affected by Soluble Solids Content and Temperature. International Journal of Food Engineering, v.10, n.3, p. 437–445, 2014.

LIMA, Í. J. E. D.; QUEIROZ, A. J. D. M.; FIGUEIRÊDO, R. M. F. D.Propriedades termofísicas da polpa de umbu. Revista Brasileira de Produtos Agroindustriais, Campina Grande, Especial, n.1, p.31-42, 2003

NASCIMENTO, J.M.C.; MOURA, M.F.V.; FONSECA, P.A.Q.; CRUZ, A.M.F.; SOARES, J.C. Determinação do Teor de Ácido Ascórbico pelo Método de Tillmans em Polpas de Frutas. CBQ 53º Congresso Brasileiro De Química, Rio de Janeiro.

MATTOS, J.S.; MEDEROS, B. J. T. Densidade de polpas de frutas tropicais: banco de dados e determinação experimental. BioEng, Campinas, v.2, n.2, p. 109-118, jan/abr., 2008