Autores

Rosendo da Rocha, K. (UFRN) ; Chiavone-filho, O. (UFRN) ; Neves Maia de Oliveira, H. (UFRN)

Resumo

Oil spilled at sea is a problem that demands an efficient and economically

feasible response. Another

apparently unrelated issue is the number of polyurethane foams accumulated in

cities and landfills

after their useful life. The present work relates these two problems so one can

be used to mitigate

the other. Post-consumer polyurethane foams were coated with hexadecanoic acid

(HA) and tested for

their ability to absorb different oils. Coated foams (HA-PC) performance was

compared to unaltered

foams (Un-PC). Oil sorption from Un-PC to HA-PC increased 0.39%, 226.88%, and

40.88% in the system

with diesel, lubricant oil S46, and 20W40 engine oil, respectively. Coating with

HA proved to be a

simple and effective surface modification to increase the oil sorption capacity

of post-consumer

foams.

Palavras chaves

oil spill; surface modification; environment

Introdução

Scientists worldwide seek to transform the actual global energy matrix into a

more sustainable one. However, petroleum dependence will still persist for

decades.

During offshore oil exploration, production, and transport, accidents may

happen, generating oil spills at sea (Soares et al, 2020). In this case,

the first intervention is to encircle the oil spilled with containment barriers,

also known as booms. Then, different oil removal methods can be applied (Hoang

and Chau, 2018). In some cases, the oil is set on fire. In others, surfactants

are used to capture the oil. Pumping the surface layer of the water-oil

interface is still commonly applied as an initial oil concentration procedure.

However, a technique that has been drawing attention is the use of hydrophobic

porous materials to capture the oil (Ko et al, 2020).

Polyurethane, for example, is a highly porous material. Although it absorbs both

water and oil, its selectivity for oil can be acquired by simple surface

modifications. This change may promote a surface with both hydrophobic and

oleophilic characteristics.

One of the main sources of polyurethane is mattresses, which are often made from

100% of this polymer. Due to flaws in environmental legislation, it is common to

find post-consumer mattresses irregularly discarded over the cities or even in

sanitary landfills. Since 2014, Brazil has produced more than 1 million m³ of

new polyurethane foam per day, which increases the need for studies on its reuse

and recycling (Grotto et al, 2020).

In this study, post-consumer polyurethane foam obtained from irregular disposal

was modified using a coating technique with hexadecanoic acid (HA). This

modification's purpose was to enhance the affinity for oil over water aiming for

oil capture in seawater. The same modification was made on new polyurethane foam

for comparison. Water and oil sorption tests were carried out and analyzed

quantitively. This work highlights the reduction, recycling, and reuse of post-

consumer polyurethane foams to remove oil spilled in seawater through simple

surface modifications. Thus, two apparently unrelated problems are addressed:

one waste is used to remove another.

Material e métodos

A 100% polyurethane mattress with a density of 18 kg‧cm-3 was

purchased from a national supplier. A post-consumer mattress with the same

characteristics as the new one was obtained from an irregular disposal area.

There was no visible damage or mechanical compaction, but there were

characteristic time-of-use stains likely from urine and sweat as well as dust

and hairs. Samples of both foams were cut into 1cm x 1cm x 1cm cubes and washed

multiple times with distilled water and 70 % (v/v) ethanol. Seawater was

obtained directly from the Atlantic Ocean (5° 52′ 52″ S, 35° 10′ 16″ W) in

Natal, Brazil, and filtered on blue band filter paper to remove suspended

solids. Diesel, lubricating oil S46, and engine oil 20W40 were purchased from a

national fuel chain. Turpentine solvent was purchased at a local supermarket.

Anhydrous ethanol (99%), and HA were purchased from Dinâmica Química

Contemporânea, Brazil. All analytical reagents were used without further

purification.

In a beaker, 200 mL of a 10 mmol.L-1 solution of HA in ethanol was

prepared. The foams cubes were submerged for 48 h in the solution inside a

sealed flask to avoid solvent evaporation. After that, the foams were washed

with 70% (v/v) ethanol and oven-dried at 60°C.

The sorption tests were performed in accordance with ASTM F726-12: Standard Test

Method for Sorbent Performance of Adsorbents. The test for determining the

amount of water/oil sorbed was performed in accordance with ASTM D95-13:

Standard Test Method for Water in Petroleum Products and Bituminous Materials by

Distillation.

The morphology of the new and post-consumer PU foams, modified and unmodified,

was analyzed by Scanning Electron Microscopy (SEM). SEM analyses required

previous gold coating. Chemical elements were semi-quantified by Energy-

Dispersive X-ray Spectroscopy (EDS) (JSM - 6610LV, Jeol, Japan). Hydrophobic and

oleophilic characteristics were evaluated in a Drop Shape Analyzer (DSA 100,

Kruss, Germany).

Resultado e discussão

Figure 1 shows SEM + EDS images for the new (N) and post-consumer (PC)

polyurethane foams unaltered (Un) and after coating

with hexadecanoic acid (HA).

It can be observed that there was no change in the pores' structure after the

chemical modification. There is also no

perceptible difference in structure between the new and post-consumer unchanged

foams, which means there was no deformation

due to the time of use. This is essential to maintain the sorption ability to

fulfill the channels with oil.

EDS analyses identified the presence of carbon, nitrogen, oxygen, and calcium in

all foams evaluated. For the HA-N, in

addition to these elements, traces of magnesium were also identified. The

presence of C, N, and O was already expected since

they are widely found in the repeater structure of the polyurethane polymer.

The presence of hydrogen is also assured. However, due to the limitations of the

technique employed, it was not possible to

quantify light elements, such as hydrogen (atomic mass = 1 u).

There was a significant reduction in the contact angle for the unaltered foams

when oil was used instead of seawater. Un-N and

Un-PC contact angles between seawater drops and their surfaces were 90.1° and

104.4°, respectively, and 77.3° and 82.2°,

respectively, between their surfaces and lubricant oil S46 drops. The HA-N and

HA-PC foams presented a 0° angle for the

sorption of lubricating oil S46. The coated foams immediately absorbed the oil

drops, leaving only entry marks. However, the

seawater drop remained as a spherical drop on the surface of HA-PC due to the

hydrophobic effect acquired. The HA-N and HA-PC

contact angles between their surface and seawater drops were 92.4° and 107.7°,

respectively. Although the HA coating did not

significantly increase hydrophobicity, there was a strong increase in oil

affinity compared to foam without coating. In a

medium containing both seawater and oil, HA-PC may be selective for oil over

water sorption, as theoretically expected.

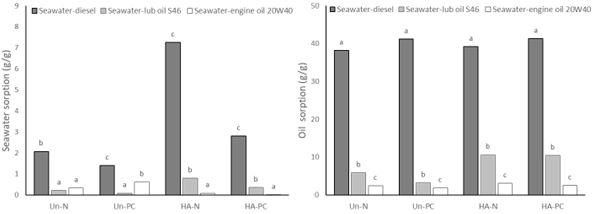

The seawater-oil multicomponent sorption tests shown in Figure 2 were performed

in three different systems.

In the first system, formed by seawater (92%):(8%) diesel oil (viscosity ~4

cSt), the water sorption ranged from 2.01 ± 0.12

g‧g-1 (Un-N) to 7.26 ± 0.22 g‧g-1 (HA-N) for new foams and

from 1.39 ± 0.02 g‧g-1 (Un-PC) to

2.80 ± 0.26 g‧g-1 (HA-PC) for post-consumer foams. The sorption of

diesel oil ranged from 38.21 ± 1.12 g‧g-1 (Un-N) to 39.19 ± 0.92 g‧g-1 (HA-

N) for new foams and

from 41.18 ± 1.02 g‧g-1 (Un-PC) to

41.34 ± 1.16 g‧g-1 (HA-PC) for post-consumer foams. In a similar

study but with a different coating technique,

Sarup et al (2022) coated new polyurethane foam with textile sludge-

derived biochar + polydimethylsiloxane and obtained

maximum sorption of 26.88 g‧g-1 for diesel.

In the second system, formed by seawater (92%):(8%) lubricating oil S46

(viscosity ~46 cSt), the water sorption ranged from

0.21 ± 0.02 g‧g-1 (Un-N) to 0.79 ± 0.02 g‧g-1 (HA-N) for

new foams and from 0.08 ± 0.01 g‧g-1

(Un-PC) to 0.35 ± 0.06 g‧g-1 (HA-PC) for post-consumer foams. The

sorption of lubricating oil S46 ranged from 5.88

± 0.11 g‧g-1 (Un-N) to 10.59 ± 0.22 g‧g-1 (HA-N) for new

foams and from 3.20 ± 0.02 g‧g-1 (Un-

PC) to 10.46 ± 0.36 g‧g-1 (HA-PC) for post-consumer foams. In a

similar study, Jamsaz and Goharshadi (2020)

evaluated the sorption capacity of hydraulic oil (similar to S46 oil) in new and

unmodified polyurethane foam and obtained

maximum sorption of 4 g‧g-1.

In the third system, formed by sea water (92%):(8%) 20W40 motor oil (viscosity

~120 cSt), the water sorption ranged from 0.08

± 0.01 g‧g-1 (HA-N) to 0.33 ± 0.11 g‧g-1 (Un-N) for new

foams and from 0.01 ± 0.00 g‧g-1 (HA-

PC) to 0.61 ± 0.02 g‧g-1 (Un- PC) for post-consumer foams. The 20W40

motor oil sorption ranged from 2.39 ± 0.12 g‧g-1 (Un-N) to 3.10 ± 0.02 g‧

g-1 (HA-N) for the new foams

and from 1.81 ± 0.02 g‧g-1 (Un-PC) to

2.55 ± 0.03 g‧g-1 (HA-PC) for post-consumer foams.

For post-consumer foams, from Un-PC to HA-PC, seawater sorption increased by

101.44% in the diesel system and 337.50% in the

S46 lubricating oil system. However, it reduced 98.36% in the system with 20W40

engine oil. The sorption of oil from Un-PC to

HA-PC increased 0.39% in the system with diesel, 226.88% in the system with

lubricating oil S46, and 40.88% in the system with

20W40 engine oil.

The results showed that, for a low viscous oil such as diesel, for example,

there was no significant difference (p-value >

0.05) between the foams, whether new or post-consumer, modified or not. This

probably happened because there was no resistance

of the pores to the diesel flow, which could mean that intermolecular forces are

not the most important factor for low

viscosity oils. Zhu et al. (2022) compared the results of gasoline

sorption on new polyurethane foam (16.55 g‧g-1) and polyurethane foam modified with

chitosan and nano-

montmorillonite (25.24 g‧g-1). Gasoline has

an even lower viscosity than diesel (> 1 cSt). These results show that even

without modification, low-viscosity oils are

easily absorbed.

When the oil viscosity was increased, the unmodified foams showed greater

resistance to oil sorption than the HA-coated foams.

This is because HA is a long-chain fatty acid and, although it has the carboxyl

group (able to form hydrogen bonds), the long-chain is formed exclusively from typically dipole-

induced C-H bonds. In this

way, the surface of the polyurethane becomes more

oleophilic and contributes to the sorption, passage, and retention of the sorbed

oil, proving the effectiveness of the

modification.

It is also important to note that post-consumer foams showed statistically

similar results to the new foams, which proves the

possibility of its use for the sorption purpose.

SEM + EDS images for new (N) and post-consumer (PC) polyurethane foams unmodified (Un) and after hexadecenoic acid (HA) coating

Seawater and oil sorption in the three systems with seawater and diesel or lub oil S46 or engine oil 20W40

Conclusões

Post-consumer polyurethane foams demonstrated similar sorption performances to

new

foams. This showed that, regardless of age or time of use of the foams,

adaptation

for oil sorption is feasible. The sorption of oil from Un-PC to HA-PC increased

0.39% in the system with diesel, 226.88% in the system with lubricating oil S46,

and 40.88% in the system with 20W40 engine oil. Coating with hexadecanoic acid

(HA) proved to be a simple, cheap, and effective surface modification to increase

the oil sorption capacity of post-consumer foams.

Agradecimentos

This work is supported by the Brazilian National Agency of Petroleum, Natural Gas

and Biofuels through the Human Resources Program PRH 44.1.

Referências

A. F726-12, Standard test method for sorbent performance of adsorbents, Annual Book of ASTM Standards, 2012.

A. D95-13, Standard test method for water in petroleum products and bituminous materials by distillation, Annual Book of ASTM Standards, 2013.

GROTTO, A. C.; HEMKEMEIER, M.; ROSSATO, M. V. Sustainability in the use of polyurethane and reuse of shavings. Research, Society and Development, v. 9, n. 1, p. 1-26, 2020.

HOANG, A. T.; CHAU, M. Q. A mini review of using oleophilic skimmers for oil spill recovery. Journal of Mechanical Engineering Research & Developments, v. 41, n. 1, p. 92-96, 2018.

JAMSAZ, A.; GOHARSHADI, E. K. An environmentally friendly superhydrophobic modified polyurethane sponge by seashell for the efficient oil/water separation. Process Safety and Environmental Protection, v. 139, n. 1, p. 297-304, 2020.

KO, T. J.; HWANG, J. H.; Davis, D.; SHAWKAT, M. S.; HAN, S. S.; RODRIGUEZ, K.; OH, K. H.; LEE, W. H.; JUNG Y. Superhydrophobic MoS2-based multifunctional sponge for recovery and detection of spilled oil. Current Applied Physics. v. 5116, n. 1, p. 1-33, 2020.

SARUP, R.; SHARMA, M.; BEHL, K.; AVASTHI, D. K.; KUMAR, P.; OJHA, S.; NIGAM, S.; JOSHI, M. Fabrication of superhydrophobic Polyurethane sponge coated with oil sorbent derived from textile sludge for oily wastewater remediation. Environmental Nanotechnology, Monitoring & Management, (In Press, Journal Pre-proof), 2022.

SOARES, M. O.; TEIXEIRA, C. E. P.; BEZERRA, L. E. A.; PAIVA, S. V.; TAVARES, T. C. L.; GARCIA, T. M.; CAVALCANTE, R. M. Oil spill in South Atlantic (Brazil): Environmental and governmental disaster. Marine Policy, v. 115, n.1, p. 01-07, 2020.

ZHU, G.; WANG, J.; YUAN, X.; YUAN, B. Hydrophobic and fire safe polyurethane foam coated with chitosan and nano-montmorillonite via layer-by-layer assembly for emergency absorption of oil spill. Material letters, v. 316, n. 1, p. 1-4, 2022.